Microlite, a type of glass microsphere, is a groundbreaking material known for its lightweight, high strength properties. These hollow spheres are extensively utilized in the oil and gas industry to enhance drilling fluid performance, reduce wellbore stress, and improve cementing efficiency. Their low-density structure minimizes hydrostatic pressure during drilling, enabling safer and more effective operations in deep and challenging reservoirs. Additionally, microlite contributes to better thermal insulation and increased durability of materials, making it an indispensable component in modern oilfield applications. As the leading suppliers of glass microspheres in India and across the globe, we take pride in delivering unparalleled quality and precision with every product. Recognized as one of the leading sellers of glass microspheres, we consistently deliver solutions that redefine standards, combining advanced technology with customer-focused service. Whether you are seeking cutting-edge materials for industrial applications or high-performance microspheres for specialized needs, Petra Microlite is your go-to partner.

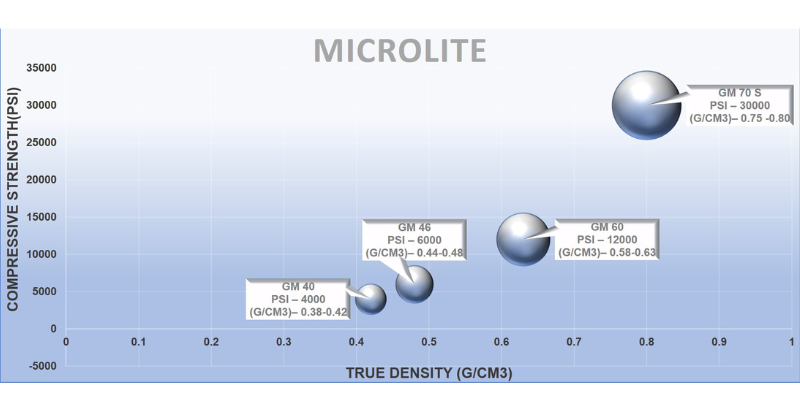

MICROLITE GM 40 and GM 46, our premium hollow glass microspheres, and their crushing strength makes them the optimal choice for cementing slurry applications in oil and gas operations.

Why Crushing Strength Matters:

The crushing strength of Microlite GM 40 and GM 46 is a defining feature, making them ideal for the most demanding cementing applications.

MICROLITE GM 40:

- Compressive Strength: 28/4000 psi

- This ensures that GM 40 remains intact even in medium-pressure environments, where alternatives like cenospheres or perlite may collapse, leading to slurry performance issues.

MICROLITE GM 46:

- Compressive Strength: 41/6000 psi

With even higher strength, GM 46 is engineered for high-pressure and high-temperature (HPHT) zones, ensuring it maintains its structural integrity and performance under extreme conditions.

Precise Advantages of GM’s Crushing Strength

1. Enhanced Durability:

- The high crushing strength of Microlite GM microspheres ensures they do not collapse under pressure, unlike cheaper fillers. This results in more stable slurry performance, even in deep wells or HPHT environments.

2.Improved Operational Reliability:

- Crushing strength allows Microlite GM 40 and GM 46 to endure the intense pumping and mixing pressures without losing their integrity. This means fewer failures and reduced risk of costly rework due to compromised slurry.

3. Better Slurry Control:

The microspheres' durability helps maintain a consistent slurry density, which is essential for optimal cementing results. This leads to better fluid flow and reduces risks like lost circulation or poor zonal isolation.

Examples Where GM Excels:

1. HPHT Environments

In challenging high-pressure zones, MICROLITE GM 46 provides superior strength, unlike alternative fillers that may fail, ensuring both the stability of the cement and the overall well integrity.

2. High-Risk Cementing Applications:

For weak or fractured formations, MICROLITE's high crushing strength ensures that slurry remains stable during pumping and placement, reducing the risk of lost circulation or gas migration.

3. Improved Well Integrity:

The durability of Microlite GM 40 and GM 46 ensures enhanced zonal isolation, leading to better long-term well integrity, which directly translates into higher ROI through better production and reduced repair costs.

CONCLUSION:

As the leading suppliers of glass microspheres in India and across the globe, we take pride in delivering unparalleled quality and precision with every product. At PETRA INDUSTRIES, we combine innovation and expertise to meet the diverse needs of industries worldwide, ensuring exceptional performance and reliability. Our commitment to excellence has established us as trusted sellers of glass microspheres, offering solutions that empower businesses to achieve their goals. Choose Microlite for superior quality, unmatched service, and a proven reputation as the preferred glass microsphere supplier in India and beyond. Experience the difference with Microlite – where quality meets innovation.

For orders or further queries, contact us here –

CONTACT: +91-7069002172

Email: sales@petraindiagroup.com

Website: www.indiacenosphere.com