In today's sustainability-driven industrial landscape, advanced materials that deliver both performance and cost-efficiency stand out. PETRA Microlite, our premium-grade hollow glass microspheres, is engineered to transform thermal insulation coatings on a global scale. Boasting light weight, exceptional thermal performance, and versatile formulation benefits, Microlite is poised to elevate products across industries.

What Are Hollow Glass Microspheres (HGMs)?

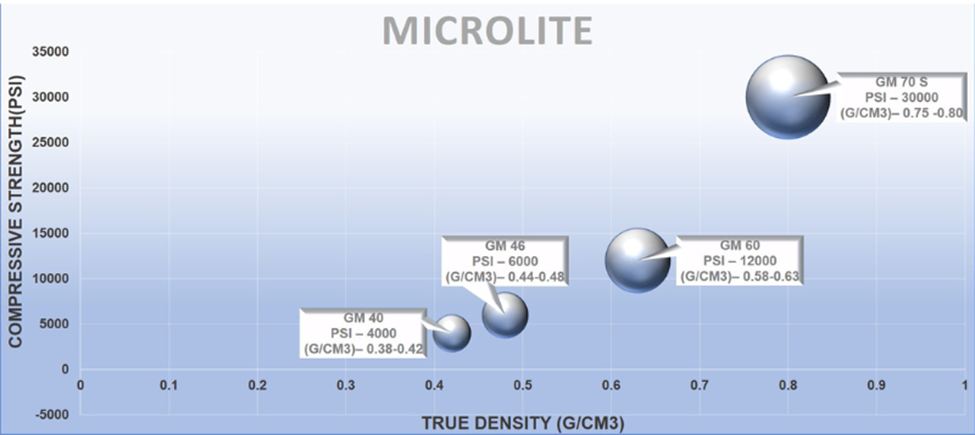

Hollow glass microspheres— also known as glass bubbles or micro balloons—are tiny spheres made of soda-lime borosilicate glass with inner cavities that encapsulate air. This structure gives them ultra-low densities (typically 0.20–0.60 g/cm³) while retaining high compressive strength. Their particle sizes range from about 2 to 130 µm, with ultra-thin walls of 1–2 µm.

Why Use PETRA Microlite in Thermal Insulation Coatings?

1. Outstanding Thermal Insulation & Heat Management

- Microlite significantly reduces thermal conductivity—its hollow core traps air and slows heat transfer, ideal for thermal insulation coatings.

- Studies show coatings with hollow glass bubbles maintain cooler surfaces, even under extreme hot temperatures—during tests at 150 °C, surfaces remained under safe touch levels (~47 °C) compared to conventional fillers.

- In solar-reflective systems (e.g., cool roof coatings), hollow microspheres enhance solar reflectance and reduce interior heat gain.

2. Lightweight, Low-Density Advantage

- With density only a fraction of conventional fillers, Microlite delivers significant weight savings. Replacing heavier fillers can save up to 40% of mass in coatings or tool boards. This not only lowers material usage but improves ease of application and handling.

3. Improved Formulation Flow & Dimensional Stability

- The spherical, hollow shape ensures superior dispersibility and fluidity in resin systems (e.g., epoxy, polyester, silicone), reducing viscosity issues and enabling higher filler loading.

- Their isotropic nature prevents uneven shrinkage or warpage—a common problem with needle or flake fillers.

4. Enhanced Mechanical & Thermal Properties

- Recent research shows coatings using HGMs coated with Al₂O₃ resulted in a 7% increase in tensile strength and a 41.7% reduction in thermal conductivity at 25 wt% loading.

- Similarly, the addition of HGMs improves dimensional stability and flammability resistance in composite matrices, such as polypropylene, phenolic resin, epoxy, or high-density polyethylene.

5. Aesthetic & Durability Benefits

- Being pure white and uniformly colored, Microlite reduces the need for expensive pigments like TiO₂, maintaining opacity while cutting costs.

- It enhances surface integrity, scratch and scrub resistance, stain resistance, gloss control, and improves overall durability.

6. Chemical Stability & Sustainability

- Made from inert glass, Microlite offers excellent chemical and moisture resistance and does not react with various resins or binder systems.

- Lower formulation viscosity can reduce VOCs and improve processing efficiency, supporting greener manufacturing.

Why Use PETRA Microlite in Thermal Insulation Coatings?

| Industry/Application |

Benefits of Microlite |

| Thermal Insulation Coatings |

Improved insulation, heat reflection, cooler surfaces, safety under heat exposure |

| Cool Roof & Exterior Coatings |

Enhanced solar reflectance, improved thermal management, durability |

| Polymer Composites |

Lightweight, dimensional stability, improved mechanical strength |

| Automotive & Tooling Boards |

Weight reduction, improved finish, fuel/battery efficiency |

| Oil & Gas Drilling |

Low-density drilling fluids, energy-efficiency, and cost-savings (industry trends) |

| Specialty Coatings |

Corrosion resistance, UV stability, anti-fouling, reduced maintenance |

(While Petra’s blog doesn’t directly cite oil & gas uses, these are well-documented uses of HGMs in broader industry applications.

Conclusion

PETRA Microlite hollow glass microspheres represent a cutting-edge solution for thermal insulation coatings globally. From dramatically improved thermal performance and formulation efficiency to enhanced durability, aesthetic finish, and sustainability, Microlite offers compelling advantages across industries. By integrating Microlite into your products, you unlock improved energy efficiency and cost savings while future-proofing formulations for the next generation of high-performance coatings.